Date: May 09, 2017Views: 1869

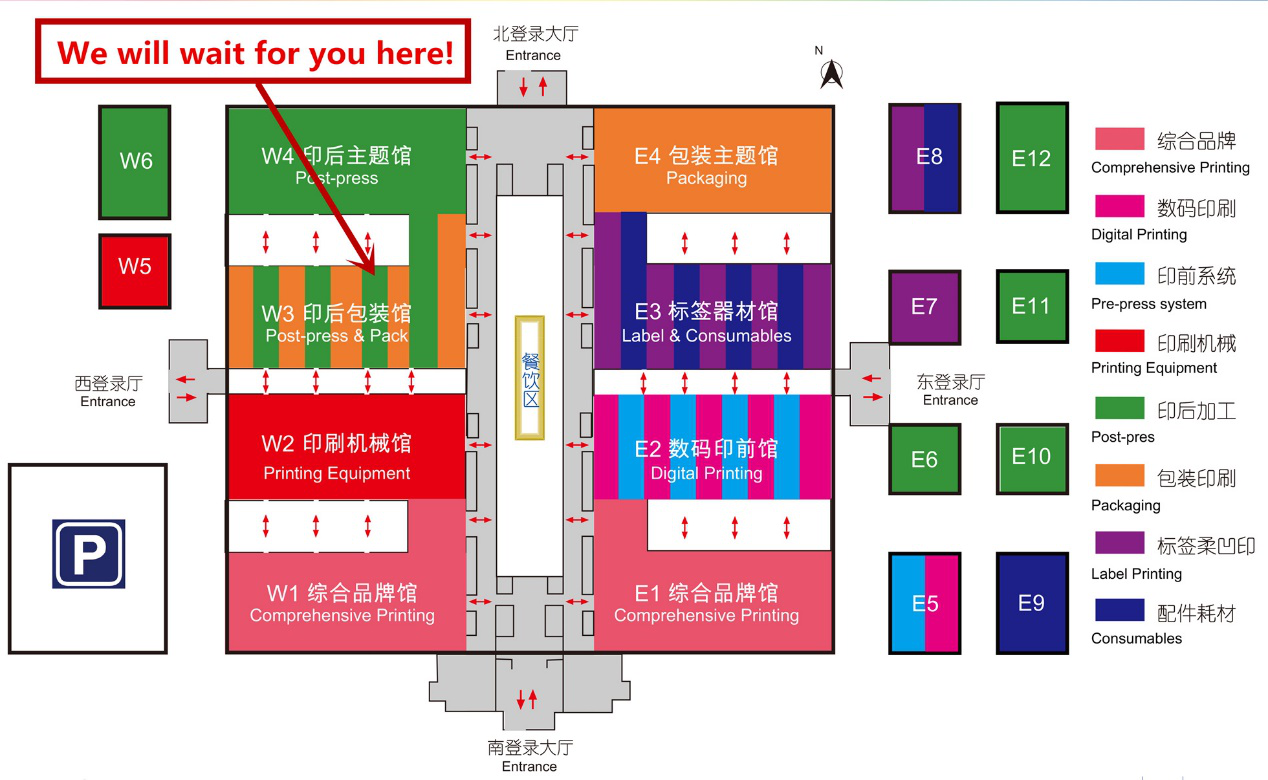

Four years passed, the 9th Beijing International Printing Technology Exhibition will be held in Beijing grandly on May 9th, 2017. As the leading brand of paper bag machine industry, Jiangsu Fangbang machinery will participate in this exhibition with a new look and show the latest technical strength. Our booth number is W3-005, looking forward to your visiting!

During the exhibition, Jiangsu Fangbang will show 4 machines integrated with the most advanced technology concept, which will surely bring you a more exciting exhibition experience.

Exhibit 1: ZD-QFP14 Fully Auto Sheet-fed Square Bottom Paper Bag Machine

※Feature:

1. Optional scissor clamp system and toggle clamp system, bring machines the advantage of coping with thin paper as well as thick paper (toggle clamp system can process some kind of paper with thickness 250gsm) .

2. Special Customized model design enlarges the production range of machines as well as the business range of customers (optional big/small side pasting device; bag width can reach 500mm or bottom size can reach 250mm).

Exhibit 2: ZD-QFB14 Fully Auto Roll-fed Square Bottom Paper Bag Machine with Flat Handle

※Feature:

1. The bottom forming hub of ZD-QFB14 makes 5 paper bags by one round, which brings apparently higher speed

than other similar traditional models.

2. By directly making flat-rope handles on paper web, customers can not only no longer rely on the traditional external hand making machine, but also be able to save 50% patch paper. What’s more, this design brings more efficient packaging and shipping for the finished paper bags.

Exhibit 3: ZD-QFJ08 Fully Auto Roll-fed Square Bottom Paper Bag Machine

※Feature:

1. Special bottom closing device improves the relatively slow bottom closing process in traditional models, so as to greatly enhance the bag making speed.

2. Distinct bottom gluing system (water glue) can efficiently save glue loss and labor cost, bringing the profit to the customers directly during the production.

Exhibit 4: YT-61300C Unit-type Flexo Printing Machine

※Feature:

1. Anilox roller inking structure effectively guarantees printing quality.

2. The machine has strong adaptability, since it can achieve satisfactory printing effect on various materials, from plastic film to corrugated board.

3. The combination of printing units is flexible, because users can increase or decrease printing unit number according to different requirements.

4. Low-cost printing plate and Low-loss printing process can effectively reduce printing cost, which is 30-50% lower than gravure printing.

Jiangsu Fangbang always builds the team in an advanced way and create innovation service based on customer first. Choose Fangbang, and let’s work together to create a better future!

We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies.