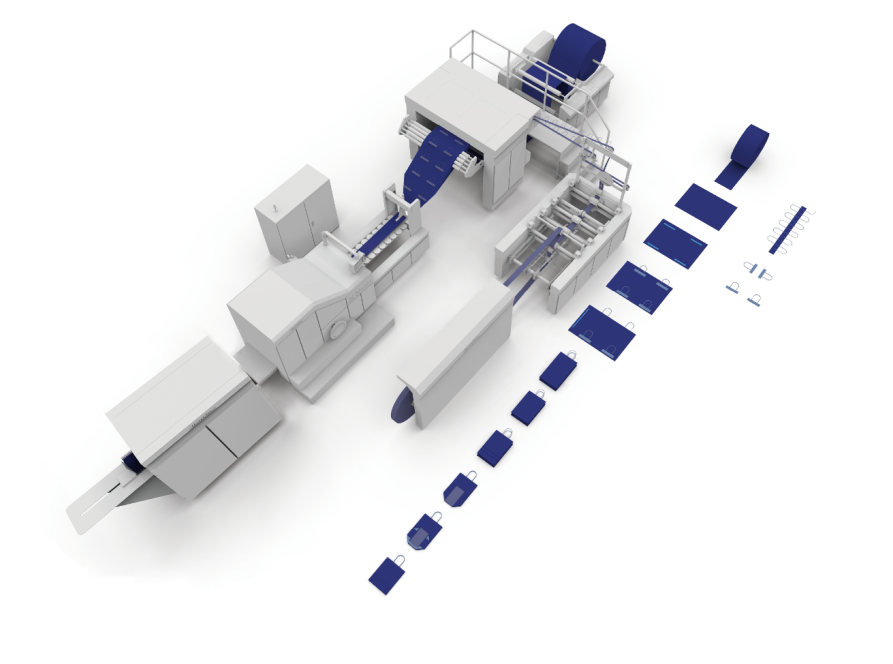

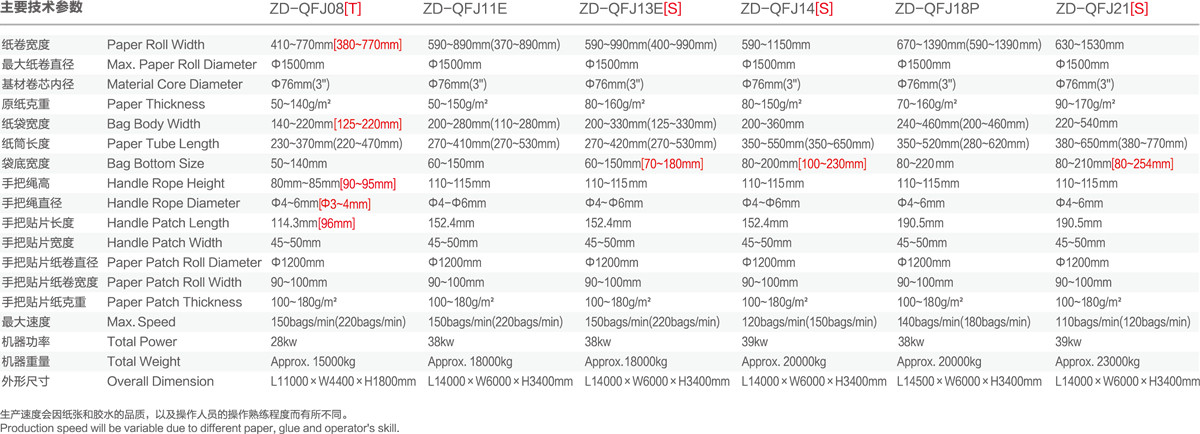

Roll-fed Paper Bag Machine (Fully Auto)

This machine is designed to manufacture square bottom paper bags with handles from paper roll, paper patch roll and paper rope, and it is an ideal equipment for producing paper handbags fast. By implementing steps including handle making, handle application, tube forming, tube cutting and bottom forming within a fully automatic process, this machine can effectively save labor costs.

This machine is designed to manufacture square bottom paper bags with handles from paper roll, paper patch roll and paper rope, and it is an ideal equipment for producing paper handbags fast. By implementing steps including handle making, handle application, tube forming, tube cutting and bottom forming within a fully automatic process, this machine can effectively save labor costs. The equipped photoelectric detector can correct cutting length, so as to ensure cutting precision. SIEMENS PLC system and adjustable dual-moulds structure, ensure that the machine can perform quickly and stably, as well as reduce adjusting time for different bag sizes. Special bags collection platform and counting function, improve packing efficiency of finished paper bags. Thanks to perfect technologies and fast production speed, this machine can produce paper handbags with high quality in many different forms, which are especially suitable for food and clothing industries.

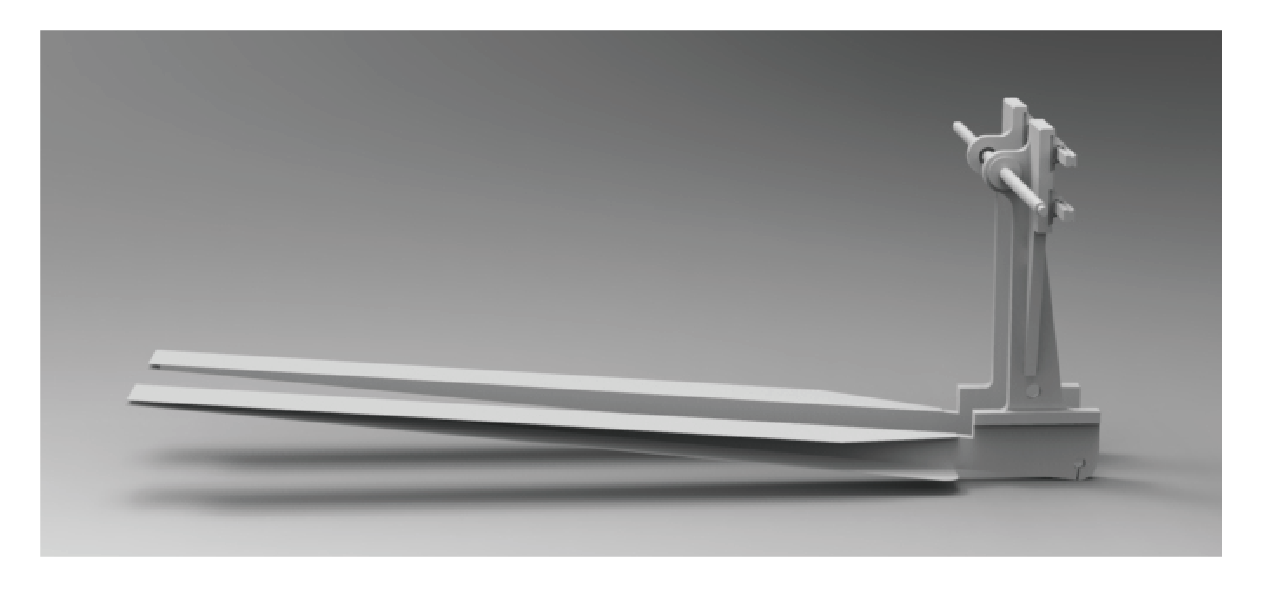

1. Special bottom closing device improves the relatively slow bottom closing process in traditional models, so as to greatly enhance the bag making speed.

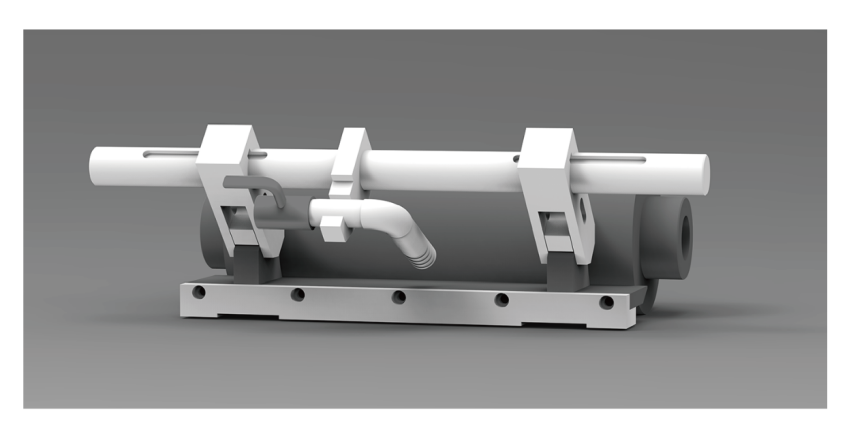

2. Distinct bottom gluing system (water glue) can efficiently save glue loss and labor cost, bringing the profit to the customer directly during the production.

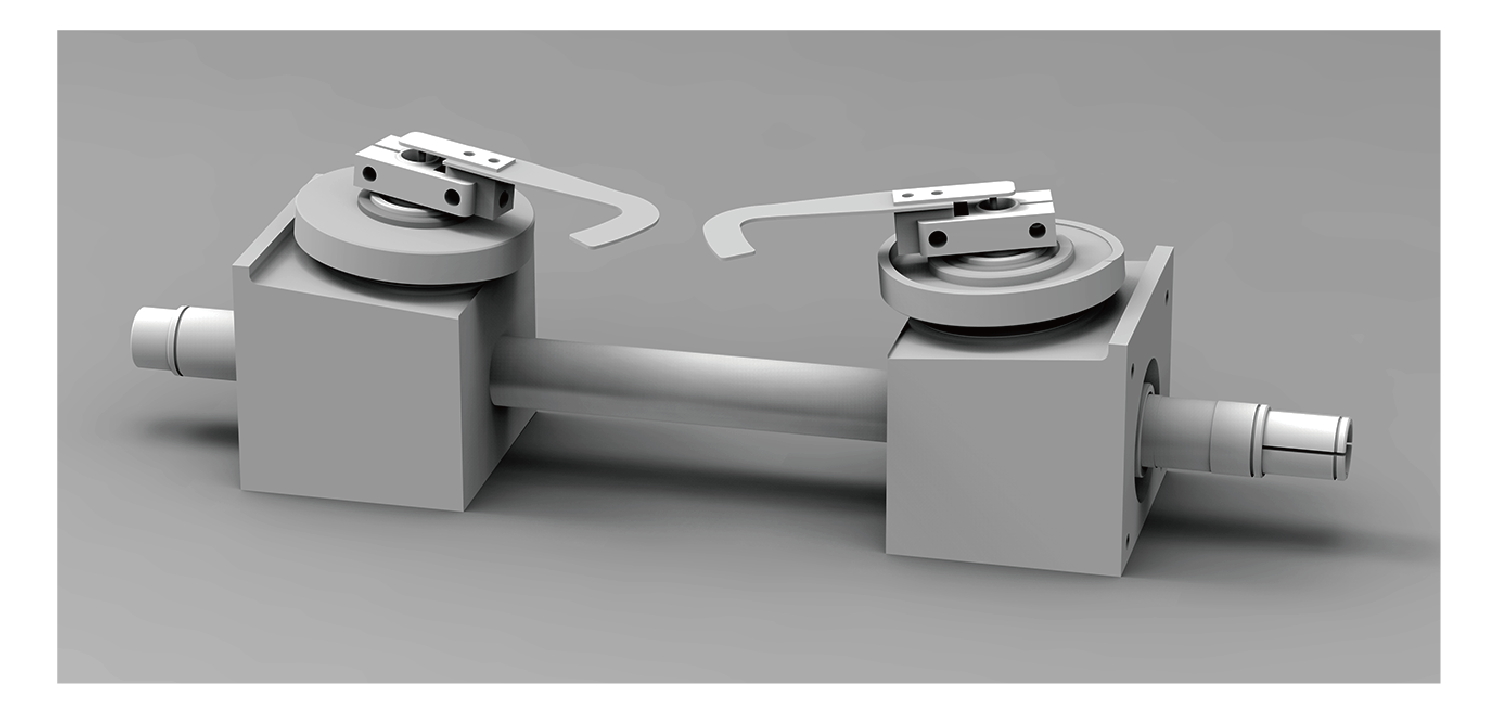

3. Adjustable dual-moulds structure (own proprietary technology) is applied on the machine, so that users can adjust bag size directly on the machine, which greatly reduces bag size adjusting time and increase production capacity.

4. SIEMENS PLC system ensures that the adjustment of cutting length can be implemented directly on touch screen, meanwhile brings efficient and stable production.

5. Tube cutter can be equipped with serrated blade or straight blade freely, so as to meetcustomers' requirements to different bag mouths.

6. This kind of machine can be connected with independent twisted handle machine and flat handle machine at the same time, so that users can not only save at least 40% investment and 45% space, but also be more flexible to paper bag market due to one-machine-two-usages.

We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies.